Transforming the Future of 3D Printing with Materialise Magics

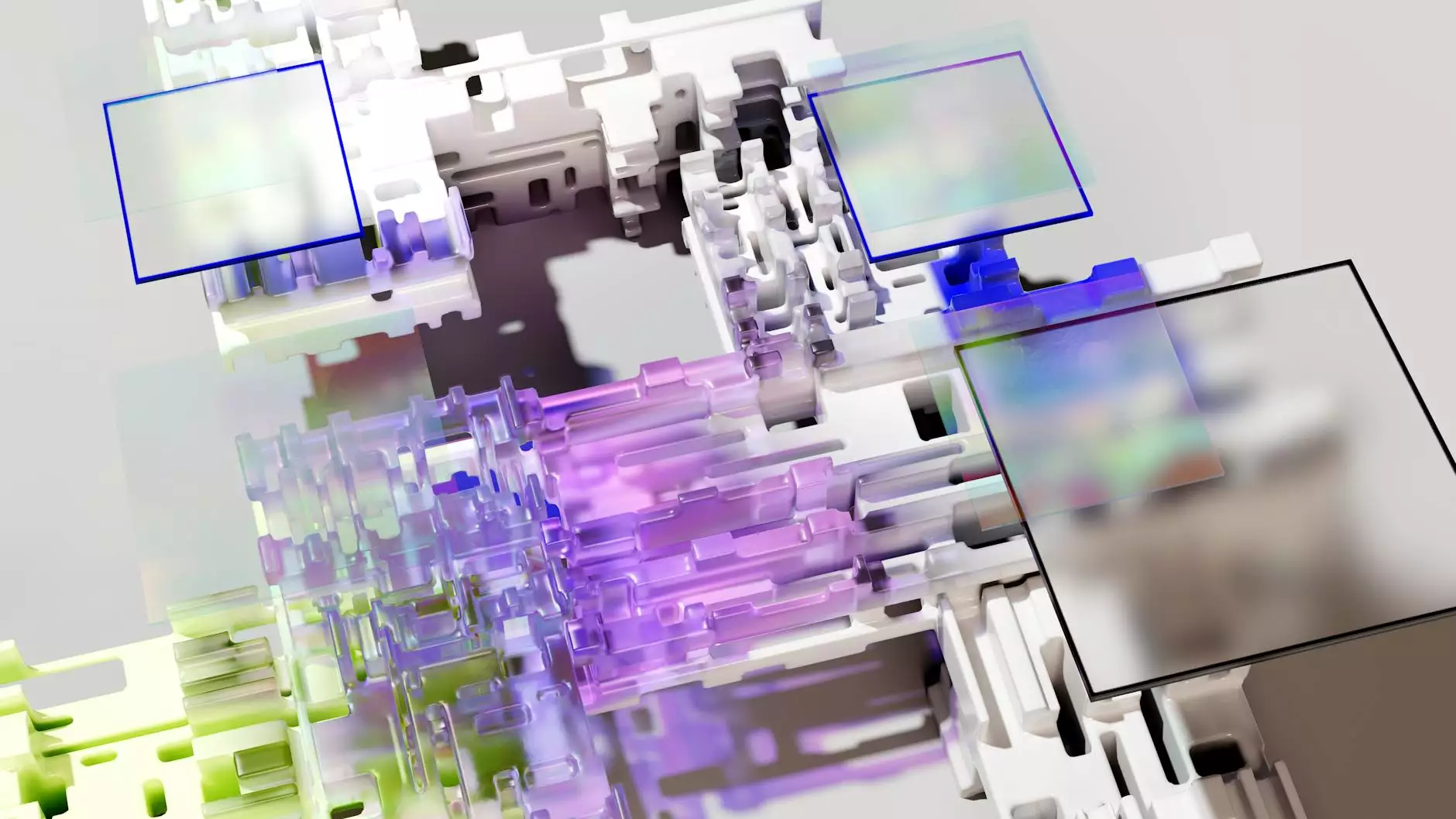

In today's rapidly evolving technological landscape, the ability to seamlessly integrate cutting-edge solutions into business practices is paramount. At the heart of the 3D printing revolution lies Materialise Magics, a software that not only streamlines the 3D printing process but also enhances efficiency and innovation in various industries. With Infotron leading the charge in 3D printing technologies, we delve deep into the transformative capabilities of Materialise Magics and explore its far-reaching benefits.

Understanding Materialise Magics

Materialise Magics is a powerful software suite designed for professionals engaged in additive manufacturing. It offers a comprehensive set of tools that facilitate the entire 3D printing workflow, from data preparation to post-processing. Unlike standard software solutions, Magics enables users to control every aspect of the printing process, thus empowering them to produce high-quality models with precision and efficiency.

The Core Features of Materialise Magics

Materialise Magics comes packed with features that enhance the 3D printing experience. Below are key functionalities that make it a preferred choice for businesses:

- Data Preparation: The software supports a wide range of file formats, allowing users to easily import and prepare STL files for printing. This flexibility ensures compatibility with various 3D printers and design software.

- Advanced Repair Tools: Magics includes sophisticated tools for file repair, addressing common issues like non-manifold edges and holes in geometry. This feature minimizes errors and maximizes print success rates.

- Build Preparation: Users can optimize layouts and nesting for optimal material usage, which translates to cost savings and reduced waste. The auto-nesting feature is particularly useful in industrial applications.

- Support Generation: The software intelligently generates support structures tailored to specific geometries, ensuring the integrity and accuracy of the final printed product.

- Post-Processing Solutions: Materialise Magics offers tools for effective post-processing, making it easy to make adjustments after printing, further enhancing the overall workflow.

Benefits of Using Materialise Magics in Business

Implementing Materialise Magics within an organization can yield a myriad of benefits. Here’s how businesses can capitalize on its features:

1. Increased Productivity

The intuitive interface of Materialise Magics allows businesses to ramp up their productivity. With quicker file preparation and seamless integration from design to print, teams can focus on innovation rather than troubleshooting issues. This is particularly advantageous for companies with tight deadlines and high production demands.

2. Enhanced Print Quality

Through the advanced repair tools and build preparation features, businesses can achieve an unprecedented level of print quality. This directly translates to fewer errors, reduced material costs, and ultimately, a better end product that meets client expectations.

3. Cost-Efficiency

By optimizing the workflow and reducing material waste, organizations can significantly lower their operational costs. The support generation feature itself saves valuable time, allowing teams to allocate resources more wisely.

4. Scalability

Materialise Magics is suitable for businesses of all sizes. Whether you are a startup venturing into the 3D printing landscape or an established enterprise ramping up production, the software's scalability ensures that it can adapt to your growing needs.

How Infotron Utilizes Materialise Magics

Infotron stands at the forefront of the 3D printing revolution by effectively harnessing the capabilities of Materialise Magics. This partnership allows us to deliver exceptional products and services to our clients. Here’s how we leverage this software:

Streamlined Workflow

By incorporating Materialise Magics, Infotron has streamlined our workflow, ensuring that each step from conception to production is efficient and cohesive. Our design to print process has shortened significantly, allowing faster delivery times.

High-Quality Prototyping

Using Materialise Magics enables us to create intricate prototypes that accurately reflect the final product. This precision is crucial in industries such as automotive and aerospace, where every detail matters.

Client-Centric Customization

We understand that each client has unique needs. With Materialise Magics, we can customize our printing processes to align perfectly with client specifications, thus enhancing customer satisfaction and fostering long-term relationships.

Real-World Applications of Materialise Magics

The versatility of Materialise Magics allows it to cater to various industries, unlocking transformative potential across multiple sectors. Here are some real-world applications:

1. Aerospace Industry

In the aerospace sector, where weight reduction is critical, Materialise Magics assists engineers in producing lightweight yet durable components. By leveraging the software’s capabilities, companies can innovate designs that push the boundaries of aerodynamics and fuel efficiency.

2. Medical Sector

The medical industry has seen groundbreaking advancements with the integration of 3D printing. Materialise Magics allows for the production of tailor-made prosthetics and implants, enhancing patient outcomes through customized solutions.

3. Automotive Industry

Automotive manufacturers rely on rapid prototyping facilitated by Materialise Magics to expedite their design cycles. This not only shortens the time to market but also ensures high-quality end products that meet regulatory standards.

The Future of 3D Printing with Materialise Magics

The future of 3D printing is promising, especially with technologies like Materialise Magics at the helm. As industries continue to evolve, the need for innovative solutions that drive efficiency and sustainability will only grow. Here are a few trends that indicate where the industry is headed:

1. Sustainable Manufacturing

The push towards sustainability is gaining momentum in all industries. Materialise Magics helps companies minimize material waste and reduce carbon footprints through its optimized workflows, paving the way for greener manufacturing practices.

2. Integration with AI and Machine Learning

As artificial intelligence continues to infiltrate various sectors, integrating AI into 3D printing processes could lead to unprecedented efficiencies and capabilities. Expect future iterations of Materialise Magics to include intelligent algorithms that further automate design and production.

3. Expansion of Materials

With ongoing research into new printing materials, including biomaterials and advanced composites, Materialise Magics will likely expand its capabilities to support these innovations, opening doors to new applications and industries.

Conclusion

Materialise Magics is undeniably a game-changer in the realm of 3D printing. Its array of powerful features, paired with Infotron's commitment to excellence, ensures that any business leveraging this software can stay ahead in an evolving market landscape. By investing in Materialise Magics, companies not only enhance their operational efficiency and product quality but also prepare themselves for the future of manufacturing.

In the world of 3D printing, the ability to materialise magics is no longer just a dream—it's a reality. Businesses that embrace this technology are positioning themselves at the forefront of innovation and success.